Today’s hygiene regulations require buildings used for food and beverage manufacture to meet specific standards in their layout, design and construction. In particular, they should permit good hygiene practices, be easy to clean and disinfect and should protect food against external sources of contamination, such as pests and bacteria.

Choosing a door that’s fit for purpose is an important part of achieving these standards. Door systems play an essential role in preventing cross contamination as well as maintaining correct room temperatures and ensuring optimum operating efficiency. Here we look at some of the key considerations in more detail.

Protection against pests and contaminants

Minimising any potential for contamination is one of the highest priorities in food processing facilities. To minimise bacteria, it is essential that doors are completely seamless and impervious in order to prevent germs building up in any hard to clean gaps or cracks in the doors surface.

Surfaces in food facilities must be cleaned thoroughly and regularly. Doors must have smooth, waterproof surfaces which are easy to clean and disinfect. They also need to be durable enough to withstand impact from traffic and vigorous cleaning procedures, which typically include very hot water, steam and aggressive cleaning chemicals. If doors start to crack, rot or peel this can reveal areas for bacteria to reproduce which will compromise hygiene.

Reducing energy costs

Door selection is also an important factor in keeping the temperature levels balanced in food facilities. Door should enable easy access for goods and people whilst also minimising air exchange. This not only improves the efficiencies of the building itself by lowering refrigeration costs and condensation, but it also improves the quality of the products.

Automated doors can be used in conjunction with air tight doors at the appropriate locations to offer a higher degree of air management control. Sealing and/or automatic doors can prevent air from travelling to areas where it’s not supposed to, improving temperature control and cross contamination.

Increasing safety and productivity

Doors need to be wide enough to allow the easy movement of staff, equipment and vehicles, but also correctly installed so that there are no gaps around the doors or frame. When doors are in frequent use (for example in loading bays) additional measures like automations and self-closing mechanisms may be necessary to increase opening speeds and help minimise pests.

Automatic or fast acting doors can be beneficial for high traffic areas in particular or where open food products are being transferred. Shorter opening times can minimise draughts, dust and contamination whilst also increasing production efficiency and saving energy costs. Furthermore, automated doors help improve staff safety and prevent damage to the door by reducing collisions.

Doors in high traffic areas and those which are likely to have equipment and forklifts passing though should be strong and able to withstand heavy impacts. Preventative maintenance should also be considered for all doors to keep them in peak operating condition and to help prevent costly downtime throughout the facility.

Fire protection and safely segregating spaces

Fire doors are one of the most critical elements of fire protection. They are an important part of compartmentation which helps to slow down the spread of fire and smoke and allow occupants to either escape the building by keeping escape routes clear of smoke and fire, or wait for rescue.

The selection and installation of fire doors which are fire tested and proven compliant by a third party approved organisation is essential. A fire door is much more than just a door leaf. The door leaf, the frame, the hinges, the fittings, the hardware, the glass in the vision panels and the seals are all dependent upon each other, to ensure the effectiveness of the door in a fire. The full door assembly must be fire tested as a combination of all elements together, rather than each component individually.

Fire doors are carefully engineered fire safety devices which should be fitted correctly by experienced installers from a reputable company. A certified fire doorset which is incorrectly installed may provide very little, if any, fire resistance at all. For this reason, specifiers should always use professional installers who are fully trained.

Security and Accessibility

Along with equipment in the facility, doors are a critical component for Food security, especially in food auditing inspection processes which are typically conducting annually by authorised accredited inspection agents.

Innovative Hygienic Door Solutions

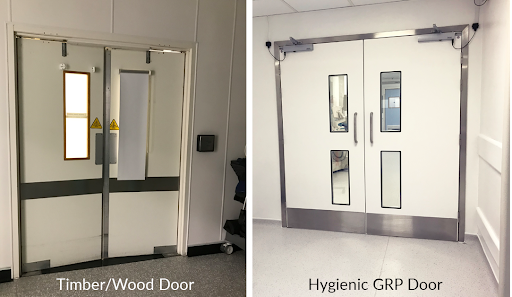

Long-term durability and high performance are achieved by specifying the most suitable door materials. Doors in food facilities will be one of the most frequently used and touched components so longevity, cleanability and durability are crucial factors. When selecting doors, food facilities commonly have four materials to choose from—steel, timber, laminate or hygienic GRP. However, in areas where hygiene is important, there is really no comparison between them. In every aspect, hygienic GRP doors perform much better than their steel or timber counterparts. The construction of steel and timber doors leaves seams and crevices, particularly around vision panels and the top and edges of doors. These harbour bacteria and are difficult to clean, creating contamination risks. Steel doors also oxidise when exposed to regular cleaning regimes, whereas timber/laminate doors warp, rot and decay when exposed to moisture.

Hygienic doors are also better value than its competitors, when lifecycle costs are factored in. Depending on the type of structure, steel doors will often require additional heavy steelwork to reinforce the door opening before installation. In high usage areas, doors are subject to a lot of wear and tear. The surfaces of steel, timber and laminate doors mark very easily and require regular maintenance to ensure hygienic performance is not compromised. Also, should they suffer impact damage, can easily dent, and cannot be repaired in situ.

Hygienic access solutions such as Dortek’s have become the leading solution for food facilities to overcome the limitations of other doors. Hygienic doors comply with all the latest good manufacturing practice (GMP) requirements in the food sector. They have a smooth, seamless construction which is easy to clean and does not harbour bacteria. The inorganic GRP door surface and core is also completely water resistant and does not warp, rust or rot when exposed to disinfectants. Doors can also be supplied and installed with numerous choices of automations, access control and air tight sealing choices to suit each opening. In addition, a huge range of colours are available for both door and frame, ensuring colour matching throughout the facility.

Hygienic Door Benefits

- Corrosion resistant – hygienic doors like Dortek’s do not rust, corrode or fail in corrosive environments or locations that require frequent wash downs.

- Completely flush construction – which is sealed on all sides, no seams, gaps or cavities for bacteria or dirt to gather.

- Custom fabrication – doors can be manufactured to virtually any standard or custom size.

- Fire ratings – hygienic doors such as Dortek’s can be manufactured with certified fire ratings up to 5 hours (using a patented hygienic concealed intumescent strip).

- Automations and activation devices – a wide range of automatic systems can be added for safe, fast and easy access.

- Insulation and airtight sealing – doors can be supplied with a range of insulation options or seals to prevent air leakage and maintain temperature control.

- Hardware options – hinges, locks and closers can fit virtually any hygienic GRP door panel.

- Solid core construction – adds strength and the ability to perform in high usage areas.

- Low maintenance and long lasting – designed to withstand heavy impacts and manufactured with a permanent gelcoat finish.

- 20+ colours options – for doors and frames, plus options for any standard RAL or BS colour to maximise aesthetics.

- Regulatory approvals – Dortek hygienic doors are approved for use in regulated facilities under the food and drug administration (FDA) including specific programs such as current good manufacturing practices (cGMP).

Dortek is a leading global supplier for the supply, manufacture and installation of access solutions, including hygienic doors for the food, pharmaceutical, bioscience, healthcare and industrial sectors. With over 50 years’ experience in designing and supplying access solutions, our dedicated in-house project management team deliver complex, bespoke door packages from initial design to final commissioning. Dortek doors are specified extensively by leading food organisations around the world. We have completed projects throughout the UK, Ireland, Europe, US, Africa, Singapore, Malaysia, New Zealand and Australia. Visit our website or contact us for further details.