Choosing the correct door system is a major factor to maintaining the delicate balance of a cleanroom or pharmaceutical environment. Door systems play an essential role in preventing cross contamination as well as maintaining correct room pressures, air circulation rates and ensuring optimum operating efficiency.

When selecting or specifying doors, architects commonly have three materials to choose from – wood, metal or fiberglass. Wood doors are suitable for lighter-duty applications where hygiene and cleanability are not priorities. For other commercial and industrial settings, hollow metal doors and frames are often seen as the default door system.

However they have limitations particularly in high-use, heavy-duty, or corrosive environments. In most cases, rust, denting and deterioration become ongoing maintenance issues that can reduce performance and shorten their useful life. In response, fiber reinforced polyester (FRP) doors and frames have become widely used to overcome the limitations of other door systems, thus providing a preferred choice.

Metal Doors

- Rust problems – moisture is the enemy of every hollow metal door.

- Welded design – interior trapped moisture means that the door begins rusting from the inside out the day after manufacture.

- Seams – lock seam design means there are visible seams, gaps, caps, etc

- Limited door sizes – metal doors are available in manufacturers’ standard sizes with custom sizes available for a premium cost.

- The weight and hinging arrangement makes steel doors extremely difficult to operate.

- Often requires additional heavy steelwork to reinforce the door opening before installation.

- Maintenance required – Metal doors must be painted after installation and maintained unless expensive stainless steel is used.

- Surfaces often mark very easily and require regular maintenance to ensure hygienic performance is not compromised.

- Hollow Panel core- Interior cavities of door can harbor dust, dirt bacteria, etc.

Fiberglass Doors

• Ease of manufacture – design is friendly to high-volume production.

• Corrosion resistant – Fiberglass doors do not rust, corrode or fail in corrosive environments or locations that require frequent wash downs.

• Completely flush construction which is sealed on all sides -no seams, gaps or cavities for bacteria or dirt to gather.

• Maintenance free – Fiberglass doors are manufactured with a permanent gelcoat finish.

• Aesthetically pleasing, available in a range of built in colors.

• Custom fabrication – doors can be manufactured to virtually any standard or custom size.

• Solid core construction – adds strength and the ability to adapt to different usage or performance applications.

• Long lasting – cost effective solution.

• 42% lighter than metal doors – easier to operate with less wear on hinges.

• Hardware options – hinges, locks and closers can fit virtually any fiberglass door panel.

• Fire rating – fiberglass doors can be manufactured and labelled with fire ratings up to 1-1/2 hours, allowing for appropriate installation in fire-rated walls.

• Regulatory approvals – fiberglass doors have earned acceptance in regulated facilities under the auspices of the U.S Department of agriculture (USDA) and the food and drug administration (FDA) including specific programs such as current good manufacturing practices (cGMP).

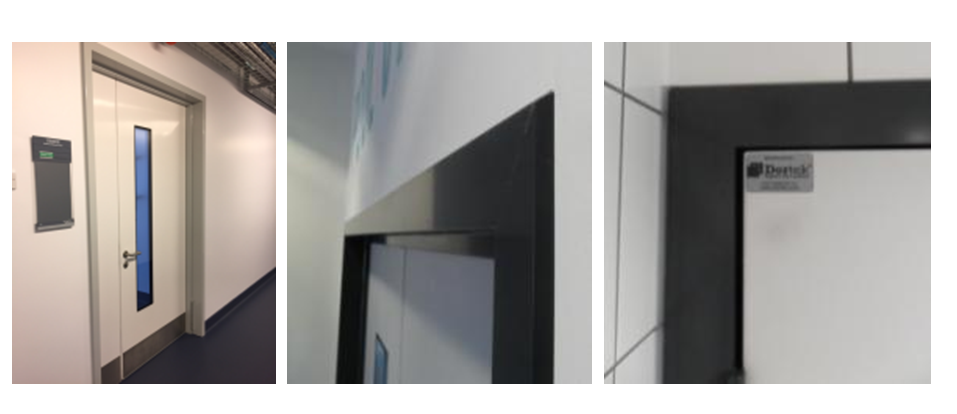

Dortek Fiberglass Door Systems

Conclusion

When reviewing design options for a facility, fiberglass doors have been shown to be the most appropriate choice for high usage and corrosive environments. Although the initial cost of the door may be higher, there is no comparison for long lasting construction and low life cycle costs.

Furthermore fiberglass doors are custom built to meet specific project requirements for a choice of colors, options and sizes. They are also readily accepted for use in USDA, FDA, and other Regulated Facilities. For all of these reasons, fiberglass doors have grown in their relatively short history to earn a reputation for high-quality products that are reliable, durable, and competitively priced.