Here at Dortek we are passionate about what we do. With over 50 years of experience in the door manufacturing industry there’s not much we don’t know. Les Blennerhassett, technical director of Dortek, Ireland’s leading suppliers of hygienic doors to the healthcare and pharmaceutical sector, explains the infection control benefits of using Dortek glass reinforced polyester (GRP) over wood and laminate doors in a hospital setting.

Specifying doors in a hospital setting can be a daunting process. The growing demands of hygiene legislation and increasing pressure on hospitals to ensure performance matches the demands of the environment, means there are now more elements to consider than ever before.

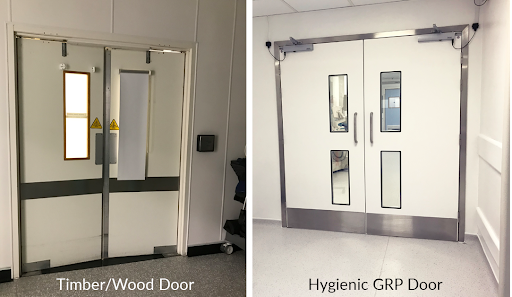

“Traditionally, hospital doors have been painted wood or wooden cored laminate. However, because of increasing standards of hygiene and infection control, GRP is becoming the material of choice for the modern hospital designer, not only for high risk areas such as intensive care, pharmacy cleanrooms and operating theatres, but also for medium risk areas like recovery suites, laboratories and hydrotherapy pools.

GRP is a high technology engineering composite, manufactured from millions of strands of glass fibre and polyester resin. Dortek Hygienic Doors are manufactured in Ireland using a unique closed mould process, creating a strong, uniform product with no seams or joints on the door surface and no holes or crevices within that might harbour bacteria.

While wooden or laminate ‘lick and stick’ doors may be adequate for non-critical areas such as corridors, waiting areas and general office space, in areas where cleanliness is of the utmost importance, organic materials are not suitable. No one would consider using organic materials to make trolleys, benches or operating tables, and yet we still see doors manufactured with timber lippings, frames and vision panel surrounds in widespread use.

In a hospital setting, doors are subject to aggressive use and wear and tear on a regular basis, with trolleys manoeuvred in confined spaces inevitably hitting both the door and its frame. In the past, concerns were purely aesthetic, and repairs could be carried out when areas were closed for major maintenance. However, when surfaces are damaged these days there is an immediate risk to infection control that must be dealt with urgently. Whereas laminate and timber doors might need to be replaced in this instance, GRP doors are much stronger, and can be easily and effectively restored to their original state.

Timber and laminate doors are not only potentially weaker than GRP doors, and thus more easily damaged, but can also pose a higher risk, as a knock or chip may reveal organic materials below where bacteria could reproduce, as well as being virtually impossible both to clean and keep clean effectively. Unlike laminate and timber doors, which can deteriorate quickly once exposed to common cleaning regimes, hygienic GRP doors like those produced by Dortek Ireland are able to tolerate constant cleaning, the prolonged use of disinfectants, chlorine releasing agents and VHP (vaporised hydrogen peroxide).

The international pharmaceutical anti biotechnology industry has already turned its back on timber and laminate doors, replacing them with GRP as standard across many manufacturing facilities. With the standards of cleanliness demanded by such industries, hospital specifiers need to recognise that the downside of infection contamination in a cleanroom far outweighs any reason not to reconsider the decades-old thinking behind conventional hospital hygienic door specification.”

For more information on door specification in healthcare and other hygienic environments, please contact us at info@dortek.com