Fire doors are one of the most critical elements of fire protection. They are used to provide compartmentation – in other words, containing fire and smoke for a period of time to allow people to be safely rescued and evacuated.

Fire doors are often the first line of defence in a fire and their correct specification, maintenance and management can be the difference between life and death for building occupants. Despite this, fire doors remain a significant area of neglect and are often the first thing to be downgraded in a specification or mismanaged throughout their service life.

A review undertaken by FDIS certificated fire door inspectors earlier this year revealed the extent of fire door failures being seen on site:

- Over 61% of fire doors inspected had problems with fire or smoke seals

- More than a third had incorrect signage

- 230 fire doors inspected had gaps bigger than 3mm between door and frame

- More than 20% had unsuitable hinges

- Almost 1 in 6 had damage to the door leaf.

(Source: FDIS 32)

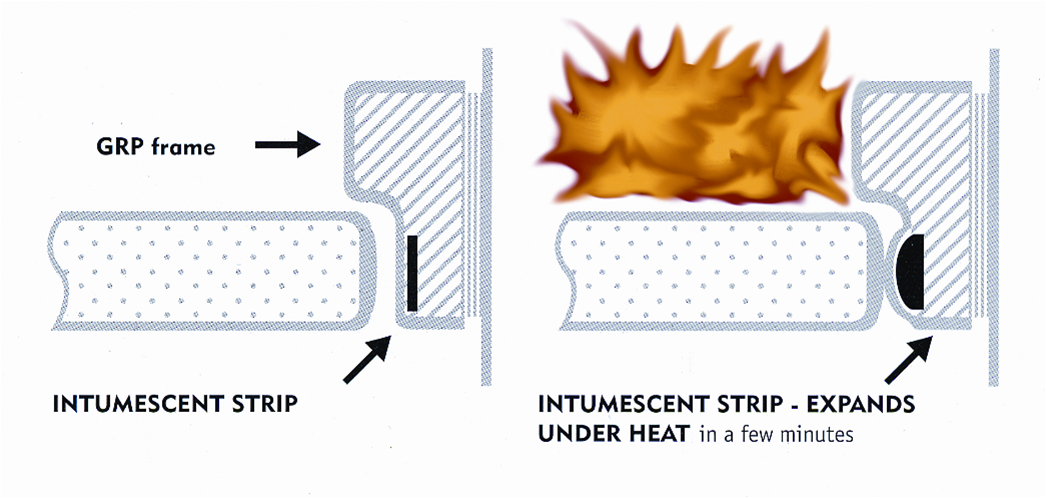

The most common identified cause of death from a fire incident is being overcome by gas, smoke or toxic fumes. Suffering from the effects of gas or smoke also accounted for one-fifth of all non-fatal casualties in 2013-14. (Source: Gov.uk) This reinforces the importance of properly specified, installed and maintained fire doors with intumescent seals that keep smoke from leaking around the edges of a fire door.

Here’s our checklist to help you specify the correct fire doors and keep them in tip top condition:

- Always use a reputable and competent supplier – many people claim to make fire doors, but only a handful have a properly tested product which is proven to work in a fire.

- Ask whether the product has been fire tested and demand to see the documentation that proves it (e.g. fire certificate or label).

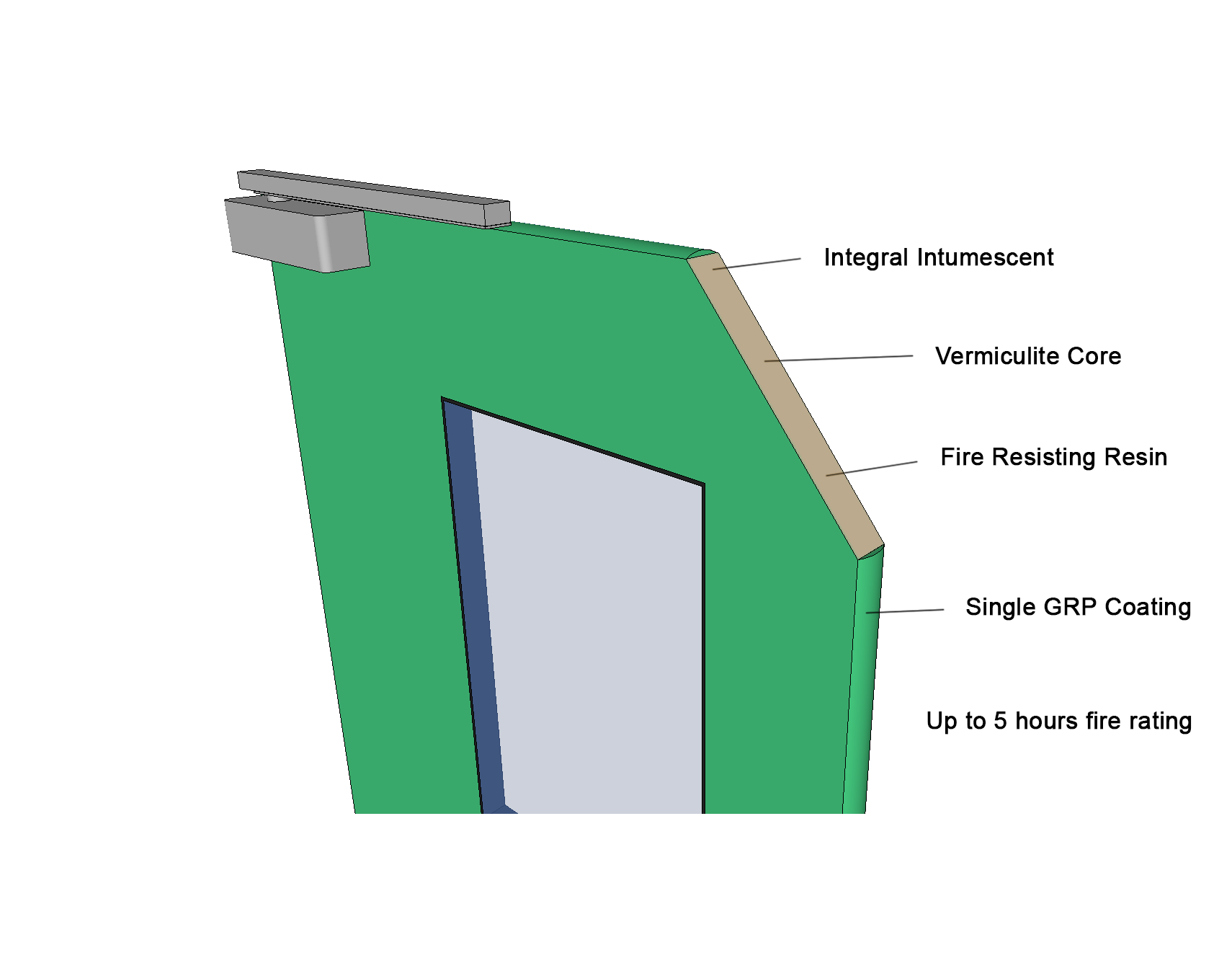

- Specifying fire doors with intumescent seals is crucial to prevent smoke inhalation in the event of a fire.

- It’s not just the door itself that matters. The frame and ironmongery is just as important – they all work together. Only buy exact compatible hardware and components from the same reputable supplier.

- Saving a few pounds on fire doors isn’t worth it. Consider the cost of damage and loss of life if a fire breaks out. Stick to the specification at all times.

- Correct installation is as important as buying the correct product – fire doors are a carefully engineered fire safety device which must be fitted correctly so make sure you use experienced installers from a reputable company.

- Fire doors should be checked regularly, and the more they’re used the more frequently they should be checked.

- Make sure you use an experienced door company to manage the servicing and maintenance of your fire doors.

- Only ever replace damaged components with like-for-like. A trained individual should be responsible for this maintenance work.