What’s the difference between Composite and Dortek GRP vermiculite-cored Fire Doors?

Dortek GRP Fire Doors

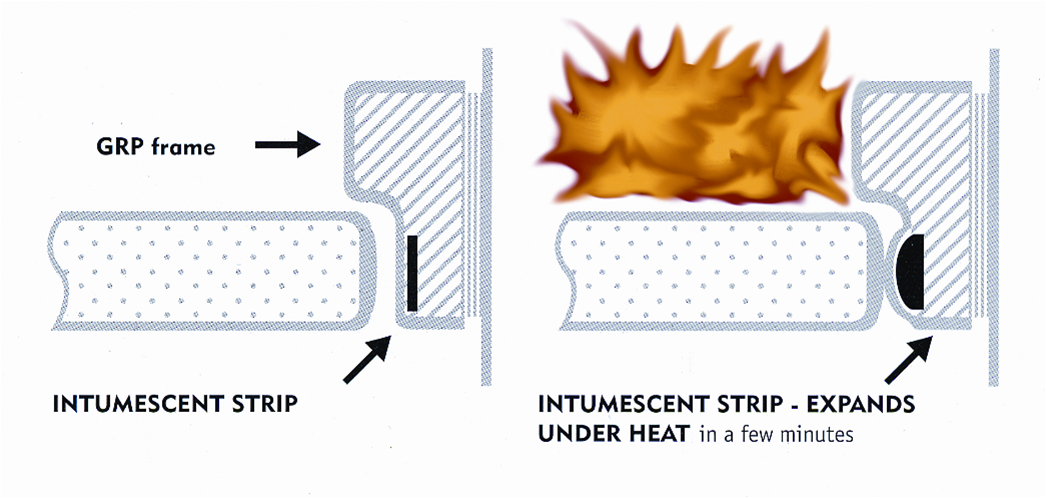

A Dortek vermiculite-cored GRP fire door is a solid vermiculite or solid reinforced concrete door with a sacrificial outer GRP skin. In the instance of a fire, the exposed GRP surface skin is a sacrificial layer that disintegrates in about 15 mins or less and has zero function in the overall performance of the vermiculite door. In the event of a fire, an integrated intumescent strip on the door expands to captivate the vermiculite core into position in the door frame before the GRP skin on the furnace side falls away.

Dortek GRP vermiculite-cored Fire Doors have undergone over 60 fire tests and achieved fire integrity of 2, 3, 4 and even 5 hours. Compare this to a “GRP composite fire door” where the glued-on GRP sheet is fundamental to give structure to the phenolic core – once the glued outer GRP sheets are burnt away there is nothing left to give structure to the fire core and the door fails after around 30 minutes.

Since 2006, all Dortek fire doors have been tested against the more difficult standards of EN 1634-1 and UL 10-C, in addition to fire testing taken place at Warrington Fire, the same Dortek fire doors have been successfully tested in Singapore, China, Malaysia and France. In stark contrast to the large overall UK market for external composite entrance doors, Dortek does not sell a single door into that market.

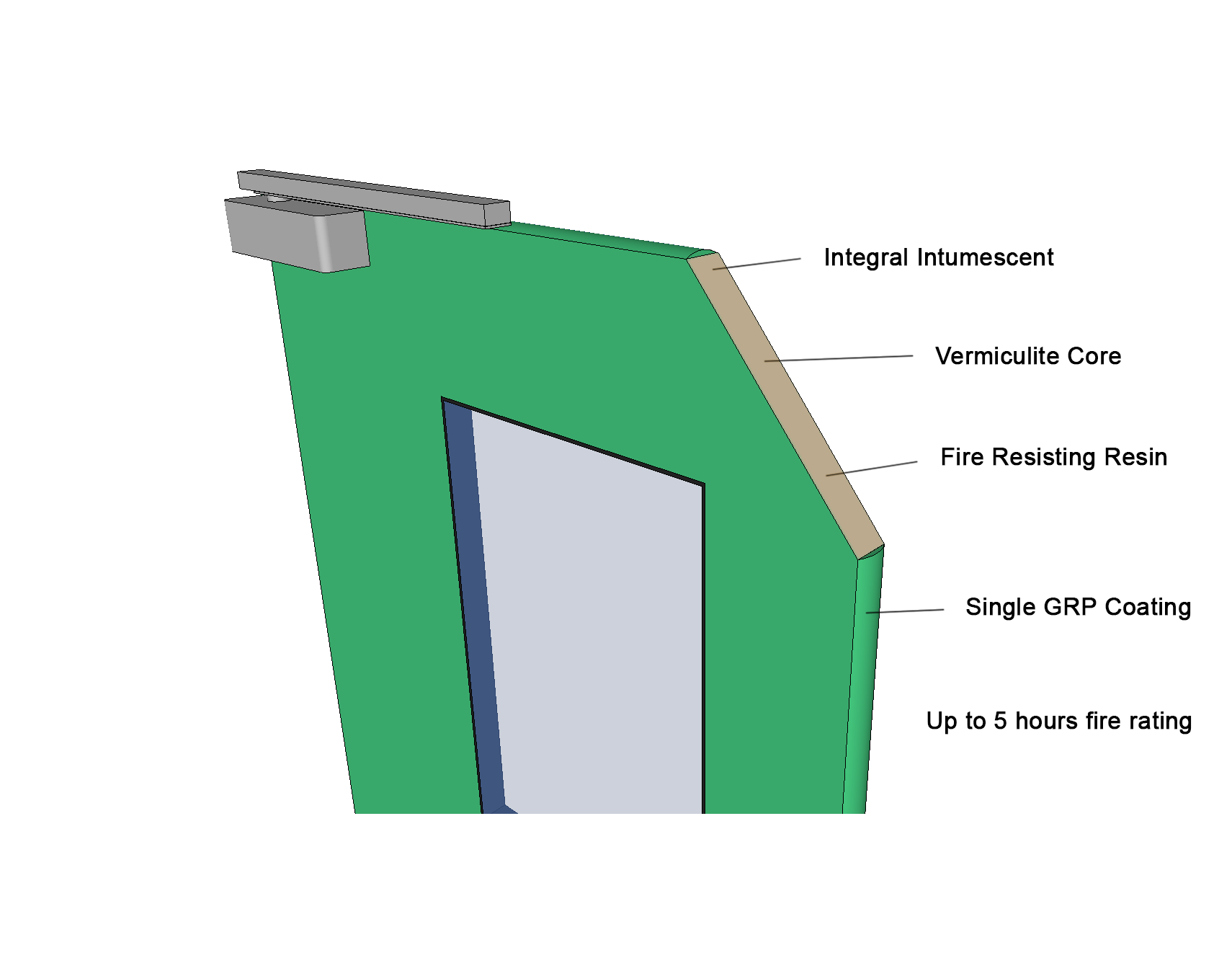

Dortek GRP vermiculite-cored Fire Door Design:

- A one-piece vermiculite core

- A single coating of liquid GRP (same purpose as paint or varnish)

- Once piece construction

- Specific fire resisting resin

- Integral intumescent

Dortek GRP Fire Door Fire Rating:

- Up to 5 hours fire rating

Composite GRP Fire Doors

These type of doors are commonly used as entrance doors and are known in the residential building industry as “GRP composite fire doors”. They usually have a fire rating of 30 minutes which is considered good for this type of door. In the event of a fire, the intumescent expands to keep the door in place until the GRP skin falls away.

A GRP composite entrance door is typically a phenolic foam core with a sheet of pre-formed GRP glued to each side, the sheet of GRP is stuck on to give the door some structure and rigidity as well as for cosmetic reasons. This method of panel manufacture is commonly known as “lick and stick” and fire doors made in this manner are typically tested to the standard of BS476.

GRP Composite Door Design:

- Two preformed sheets of GRP to give the door structure

- PVC frame (to which sheets are glued to)

- Phenolic foam core (injected into void between sheet)

- External intumescent

GRP Composite Door Fire Rating:

- Typically 30 minutes

GRP Composite Fire Doors Dortek GRP Fire Doors