Hospital Infection Control: The Importance of Selecting the Right Hospital Doors

Here’s some advice about key design considerations when specifying doors in hospitals and other hygiene critical facilities.

Since microorganisms can be transmitted by contact, choosing the right doors can make a huge difference to infection control. Hospital doors can be a major source of contamination as they are the piece of equipment which is touched the most by patients and staff. Hospital doors are also vital for controlling clean air and traffic flow. This is why it’s crucial that the correct door is chosen as it can significantly affect the risk of infection.

Making the right door choice

When specifying hospital doors, considering the following points will not only help infection control, but it will also ensure building regulations are met and the doors operate efficiently, with a long, trouble-free lifespan.

- Hygiene performance

- Inorganic door construction

- X-ray and laser protection

- Hermetic sealing for clean air control

- Fire and smoke regulations

- Automations and accessibility

- Strength, durability and maintenance requirements

- Sound insulation

- Life cycle costs.

Choose Hygienic Door Materials

One of the most important aspects of a successful infection control policy, is choosing the correct materials for both the construction of the room and the components within it.

The Health Building Note 00-09: ‘Infection control in the built environment’ offers valuable guidance for architects and specifiers. ‘Doors should be cleanable, that is, smooth, non-porous and fluid resistant’. This is particularly crucial in areas where infection control is paramount.

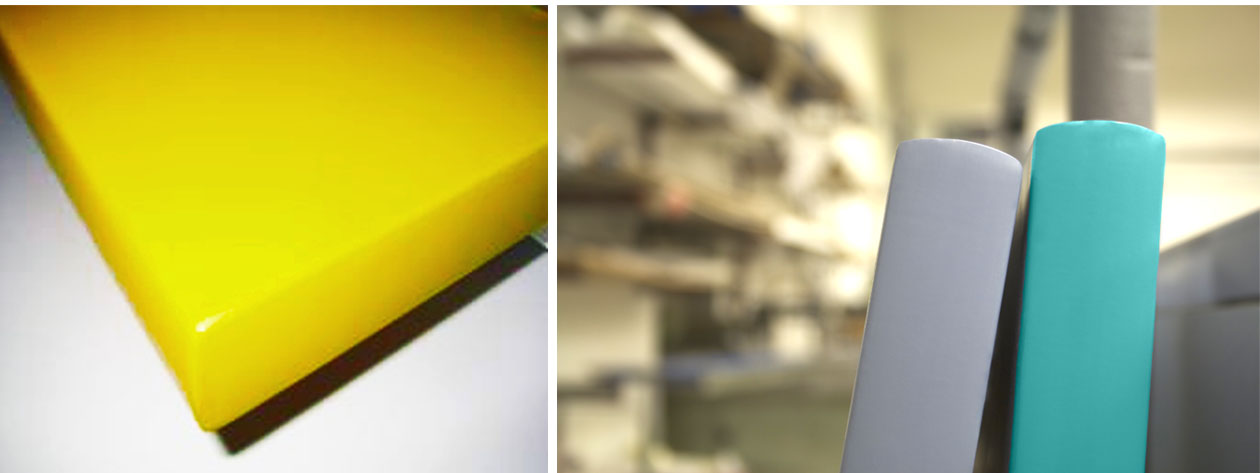

Hospital doors should be carefully selected to ensure they are constructed using an inorganic hygienic material such as GRP (Glass Reinforced Polyester). Doors should also be easy to clean and resistant to moisture and disinfection procedures. A smooth construction should be defined as seamless with no texture, voids, reveals or laminated components which can harbor bacteria.

Specifying hygienic GRP doors for infection control

Hygienic GRP hospital doors are manufactured from a high technology moulded composite which has been independently tested. Laboratory tests conducted by IMSL (Industrial Microbiological Services) prove that hygienic GRP doors help prevent bacterial and fungal growth. Dortek Hygienic GRP doors have been independently tested by IMSL for resisting infections such as MRSA, Aspergillus Niger, Staphylococcus Aureus & E Coli.

Critical to the doors hygienic performance is its one-piece moulded GRP construction with no seams, joints or voids where bacteria, dust or dirt can build up undetected. The inorganic construction and water repellency of Dortek doors provides no sustenance for harmful microorganisms. Hygienic GRP hospital doors have no lips, joins or edges (even around vision panels). They have an easy to clean surface which is unaffected by moisture or common cleaning chemicals and disinfectants. Colour is also built into the gel coat of the door to provide continuous long-lasting protection, which is not reduced by impact damage.

Hermetic sealing for clean air control

Hermetically sealing doors should always be considered for reducing cross contamination through air flow in high risk areas such as operating rooms and patient isolation areas.

Hygienic GRP hospital doors can be supplied with hermetic sealing options for controlling air. Hermetic hygienic doors have a unique patented track system so it seals perfectly against the floor and frame. The efficiency of the seal has been officially tested and results show it to be over 99% effective thus helping to reduce the spread of airborne infections, cross contamination and air handling costs.

Third party tested fire ratings and lead protection

In certain areas of a hospital, evacuation in the event of a fire is almost impossible. Intensive care units and operating theatres are obvious examples. Fire doors are often the first line of defence in a fire and their correct specification can be the difference between life and death for building occupants.

Hygienic GRP doors have a vermiculite-core and can provide up to 4 hours fire protection. Vermiculite is a mined mineral rock, which is classed as non-combustible. Hygienic GRP fire doors have been third party tested and have a patented concealed intumescent strip built into the door. This maintains a smooth seamless profile ensuring that there are no seams or ledges where dirt and germs can gather. It is also ideal for high traffic areas as it never comes lose or needs to be replaced. Hygienic GRP doors can also be supplied with x-ray ratings and sound insulation for the added protection of patients and staff.

Touchless automations to reduce cross contamination

Hygienic GRP Doors can be automated to provide hands-free entry and further reduce the risk of infection. The doors use an intelligent automation which is key for user safety. The automations react to the smallest obstruction and photo sensors stop the door from closing onto passing traffic. Doors can also be provided with access control systems, locking and interface with BMS (Building Management Systems) for extra security.

Durability and life cycle costs

With sustainability at the forefront of the healthcare sector, doors which require frequent servicing or redecoration should always be avoided. Hygienic GRP doors are up to 42% lighter than wood or laminate doors. This removes any need for expensive maintenance work or replacement due to excessive wear on hinges and closers. GRP is an exceptionally strong and heavy-duty material which gives it the lowest whole life cycle costs in comparison to other alternatives.

Complete project management from specialists with over 50 years’ experience

Dortek has over 50 years’ experience working in the healthcare sector and has completed over 2000 projects for the NHS, international healthcare authorities and the private sector.

Dortek’s in-house project managers work with architects to provide fully integrated, hygienic door systems which help to improve both infection control rates and operational costs. Dortek hygienic GRP doors are extremely versatile and can meet a wide variety of performance characteristics to suit all healthcare applications. This includes requirements for hygiene, fire ratings, smoke, air sealing control, touch-free automations, x-ray and laser protection, acoustics, water resistance, infection control and durability.

For these reasons Dortek hygienic GRP doors are specified by hospitals, architects, healthcare planners and infection control departments across the world.

Just some of the hospital’s already benefiting from using Dortek’s hygienic GRP hospital doors.

- The London Clinic, Harley Street, UK

- Great Ormond Street Hospital, UK

- School of Hygiene and Tropical Medicine, UK

- Royal London Hospital, UK

- Guys and St Thomas Hospital, UK

- New York-Presbyterian Hospital, US

- Yale University Hospital, US

- National Children’s Hospital, US

- Baptist Health South Florida, US

- St. Luke’s Hospital, US

- Sengkang General Hospital, Singapore

- Ng Teng Fong Hospital, Singapore

- Singapore General Hospital, Singapore

- KK Women and Children’s Hospital, Singapore

- National Heart Centre (NHC), Singapore

- National University Hospital, Singapore

- National Centre for Infectious Diseases, Singapore

- Alice Spring Hospital, Australia

- Vincent’s Private Hospital, Australia

- Royal Adelaide Hospital, Australia

- Mercy Hospital, New Zealand